Lorem ipsum dolor sit amet, dolor siterim consectetur adipiscing elit. Phasellus duio faucibus est sed facilisis viverra. Umero praesent nec accumsan nibh, eu grav da metus.

Managing Product Stock & Inventory on Kingston Express

2 min read

- Why Stock Management Matters

- Step 1: Enable Stock Management for a Product

- Step 2: Set Stock Quantity

- Step 3: Set Low Stock Threshold (Optional)

- Step 4: Out of Stock vs In Stock

- Managing Stock for Variable Products

- What Happens When Stock Reaches Zero?

- Common Inventory Mistakes

- Best Practices for New Sellers

- Inventory & Cancellations

- Final Tip

Good inventory management keeps your store organized, honest, and profitable.

Nothing hurts a seller faster than selling items you don’t actually have.

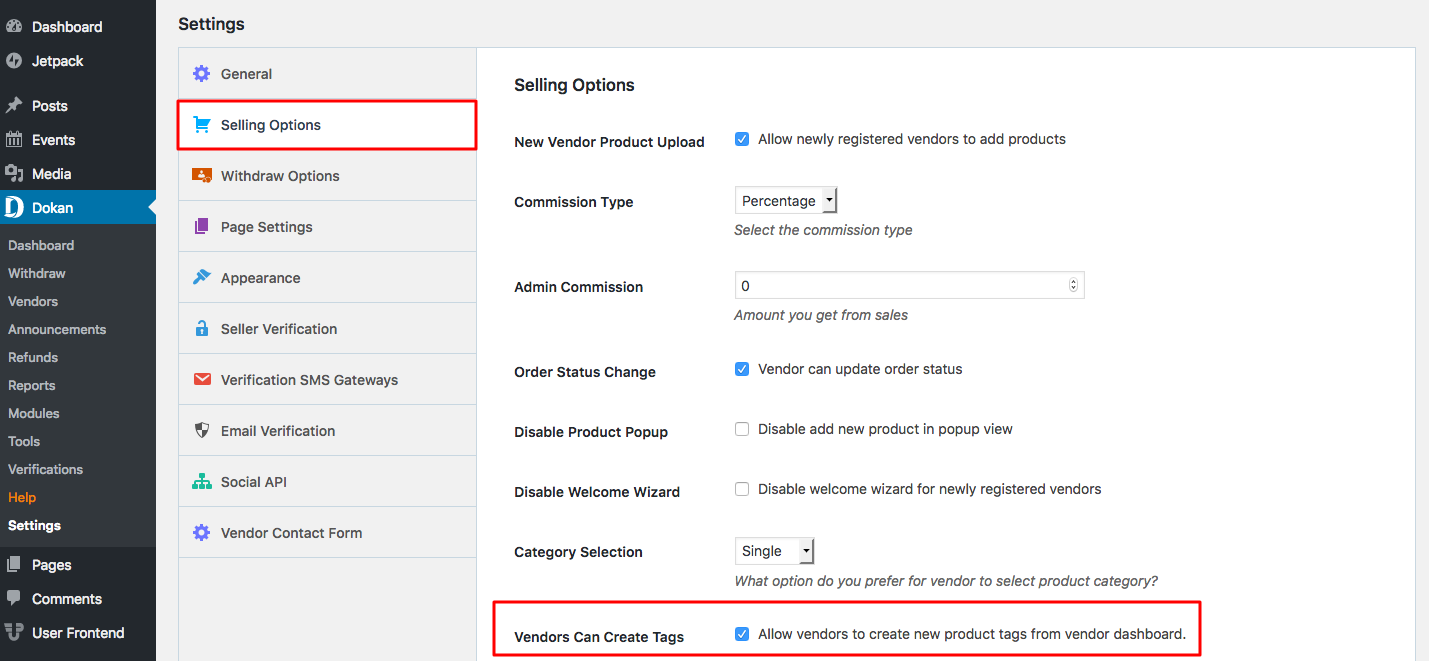

This guide shows you how to manage stock properly using Dokan Multivendor — even if you’re new.

Why Stock Management Matters #

Proper stock control helps you:

- Avoid cancelled orders

- Prevent customer complaints

- Maintain good seller ratings

- Know when to restock

📌 Out-of-stock surprises = bad reviews.

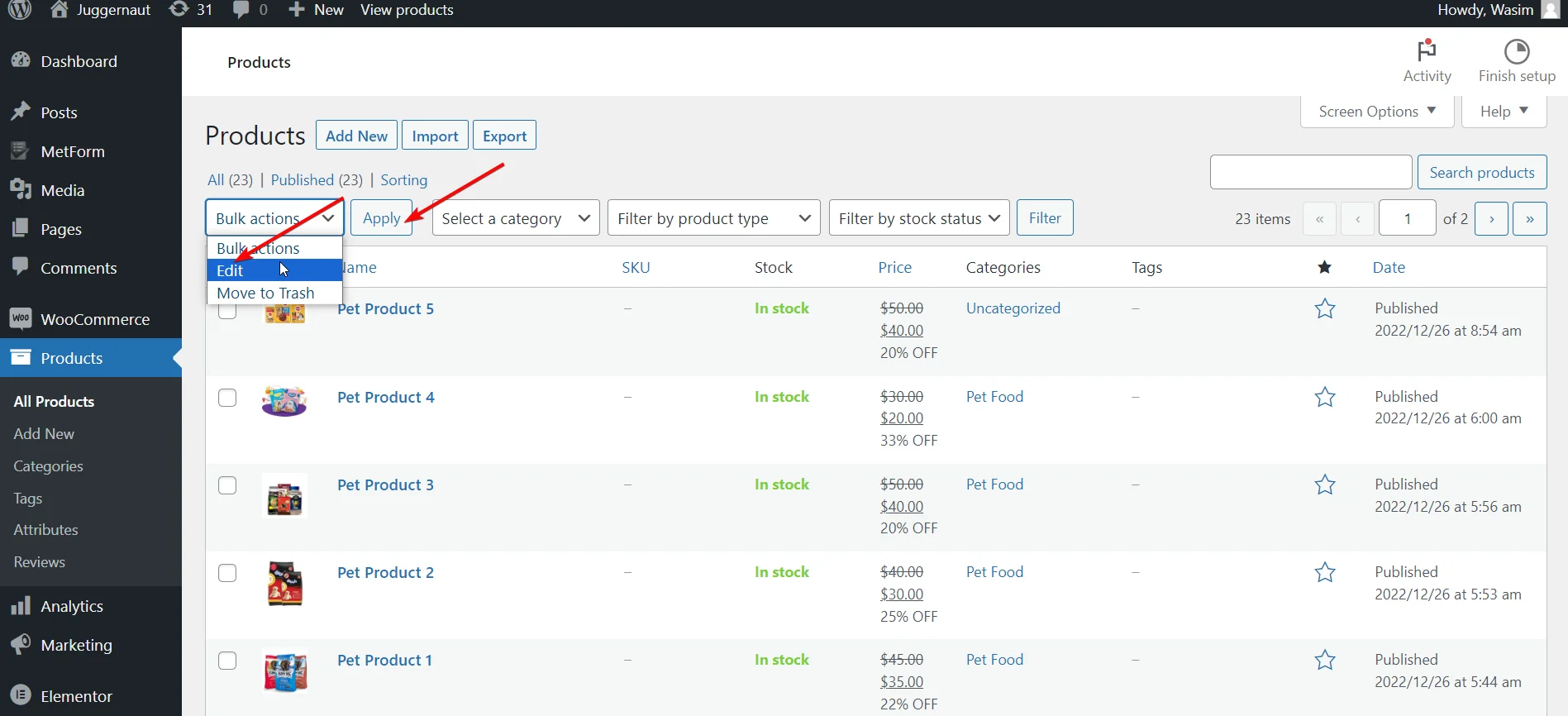

Step 1: Enable Stock Management for a Product #

When editing or adding a product:

- Go to Inventory

- Check Manage Stock

- Enter your stock quantity

📦 This tells the system how many items you actually have.

Step 2: Set Stock Quantity #

- Enter the number of items available

- Example: 10, 25, 100

📌 Be honest — don’t guess.

Step 3: Set Low Stock Threshold (Optional) #

Low stock alerts:

- Notify you when stock is running low

- Help you restock before selling out

🔔 This is especially useful for fast-moving products.

Step 4: Out of Stock vs In Stock #

You can manually set:

- In stock → product is available

- Out of stock → product cannot be purchased

🚫 Out-of-stock items are usually hidden from checkout.

Managing Stock for Variable Products #

For variable products:

- Each variation has its own stock

- Example:

- Size M: 5 left

- Size L: 0 (out of stock)

📌 Always update variations separately.

What Happens When Stock Reaches Zero? #

When stock hits 0:

- Product is marked Out of Stock

- Customers can’t place orders

- Prevents overselling

✅ This protects you.

Common Inventory Mistakes #

❌ Not enabling stock management

❌ Forgetting to update stock after offline sales

❌ Guessing quantities

❌ Leaving discontinued items in stock

⚠️ These cause cancellations.

Best Practices for New Sellers #

✔ Start with small quantities

✔ Update stock daily (or weekly minimum)

✔ Pause products you can’t restock quickly

✔ Use low-stock alerts

Inventory & Cancellations #

If you cancel orders due to no stock:

- Ratings may be affected

- Customers lose trust

📌 Accurate stock prevents this.

Final Tip #

Stock management isn’t fancy — it’s discipline.

If your stock is accurate, everything else runs smoother 📦✅

Jamaica

Jamaica